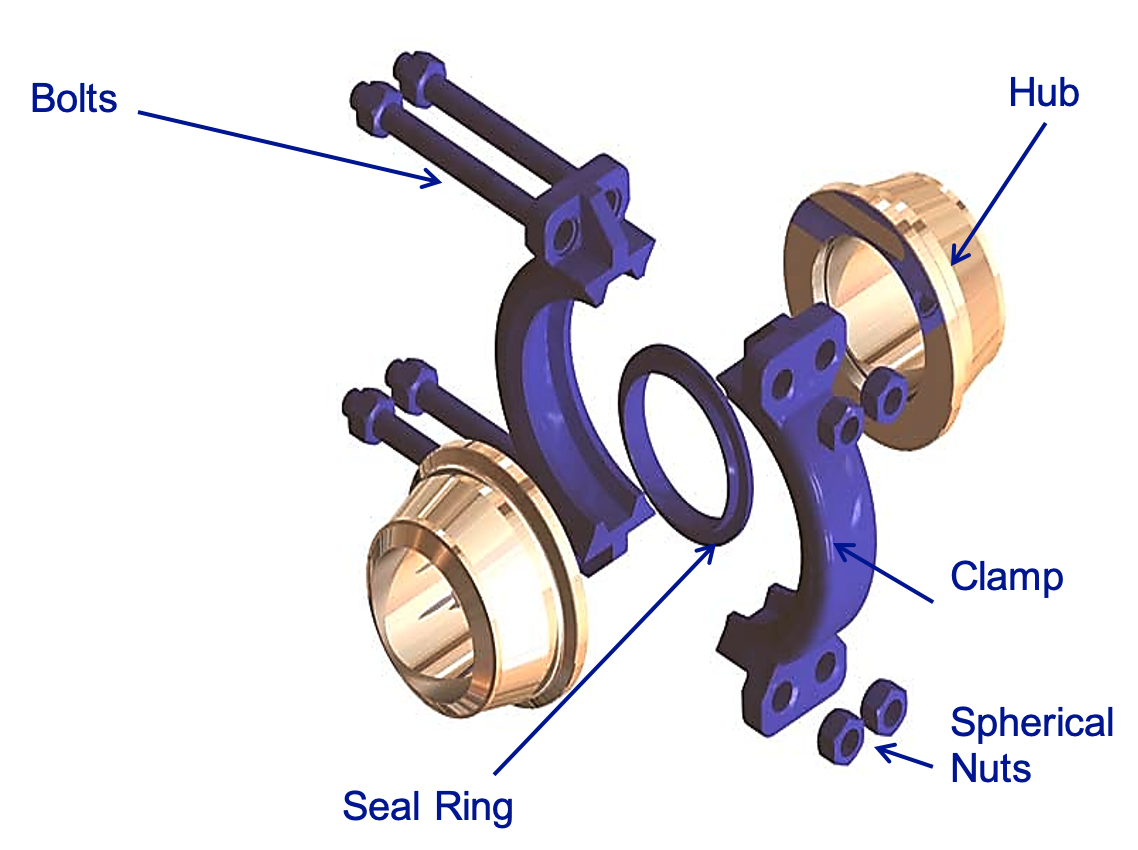

Hub Type Clamp Connection

A Hub Type Clamp Connection comprises of four bolts, two clamps, two hubs and a seal ring as shown below.

The sealing ring is clamped in position between the two adjoining hub faces. By applying an evenly distributed load to the two halves of the clamp deflection on the sealing ring faces takes place giving a self energised seal.

Measurements should be taken taking care to maintain the standard manufacturer’s requirements.

A controlled tightening sequence should be carried out firstly in stages and then a final chase sequence.

The seal ring and the hub sealing faces may require lubrication before assembly. Manufacturer’s recommendations will specify the lubricant and its use.

Many manufacturers produce designs of compact flanges which are virtually identical to the Grayloc. For example Flexitallic, Destec, Seaboard Lloyd, Techloc, Spolok, etc!

Flanges – Do’s and Don’ts

Do’s

- Always read carefully the manufacturer’s procedures as each of these procedures will be different making it crucial to use the correct one.

- When assembling compact flanges that consist of two clamps such as Hub Type Clamp Connection, always align the clamps such that they sit to the left and to the right of the pipe as opposed to top and bottom. This prevents water from collecting in the clamps.

- Many manufacturers state that their gaskets may be re-used. Always inspect a gasket for damage, deterioration and wear before re-using it and make notes on any paperwork that may be required to be completed. These notes become part of the permanent history of the joint.

Don’ts

- Never attempt to ‘mix and match’ parts of different compact flanges. They may look the same but none are interchangeable.

- Only use the parts from the specified flange manufacturer.